"Having fewer total turbines means a wind farm could space them farther apart, avoiding airflow interference. The turbines would be nearly twice as tall, so they’ll reach a higher, gustier part of the atmosphere. And big turbines don’t need to spin as quickly, so they would make economic sense in places with average wind speeds around 5 meters per second… "

Shipping them in multiple pieces and reassembling them on-site won’t work because the joints would create weak spots.

Not qualified to have any opinion on this topic, but from a laymans perspective that sounds like an easier problem to solve than developing a gargantuan steel T-Rex with wings just for deployment of blades?

The forces on a blade of this size are truly staggering, when you think about how long a lever they are attached to only one side, its clear that the issue is not only strength at the seam of a proposed joint but also the impact any additional weight will have on the junction of the blade with the rotor. They are pushing the limits of what high pressure molded composites can handle at these scales, but still some companies have developed multi-piece turbine blades.

Generally the biggest downsides to multi-component blade technologies are that they cost substantially more, and they have lower operating lifespan, a bad double whammy for the profitability of a windmill.

Basically the cargo plain developers are banking on the cost per flight of each turbine blade being less than the cost of building, installing, maintaining, and replacing multi-part blades over the lifetime of the windmill, and as of now this economics pencils out. Who knows though, tech changes fast, what I wonder is whether portable blade foundries might not be possible to build the blades on-site for large windmill projects.

If you want to get into the nitty gritty I found this presentation very helpful: https://windmillstech.com/wind-turbine-design/

we already know how to build bigger planes. the lockheed CL-1201 design study is from like the 60s.

I’m no Boeing engineer, but the design on the thumbnail does not look airworthy at all, the wings are too small and probably too far rearward to generate the necessary lift. And only 4 engines? Look up pictures of the late An-225 for an actual superheavy airlifter.

Did you read the article? It addresses those items.

Read? An article?

You need wing area and engine power to carry weight, not to carry space. That plane is made to carry extremely lightweight wind turbine blades that take up a lot of space but are very low density.

Yes, if you fill that payload area with iron, it won’t fly. But if you use it for its intended purpose, the wing area is large enough.

The An-225 was designed to carry 253 tons about 2500 miles. This aircraft needs to carry just 75 tons, and could get away with about a 1000 mile range.

This is not supposed to be a superheavy airlifter. Supersized, yes, but wind turbine blades are very light for their size.

Lmao, it’s like a flying T-Rex.

How about smaller and more capable windmills?

Doesn’t tap the higher altitude stronger winds.

It’s literally designed to furl up in stronger winds. Did you not watch the second video?

That’s literally the opposite we are talking about here.

The point of large turbines is that they get high enough up where winds are stronger so that it can take the stronger winds up there and convert them into electricity.

You are talking about a design that furls up to NOT take in stronger winds.

No, we don’t need tiny wind turbines that already won’t make a lot of energy because they are too small and that then even shut down as soon as winds become strong enough to make it worthwhile.

Also, every commercial wind turbine can rotate its blades, and when winds become dangerously strong, they just turn the blades flat into the wind so that less of the wind (or none of it) actually turns the rotor.

Also, the inventor of Harmony Turbines covers one of the big drawbacks of conventional turbines. Conventional ones use brakes in strong storms to slow down, which can and will overheat and cause them to burn up and even explode.

Harmony Turbines however aren’t meant to completely stop at all, I think you misunderstood how the furling mechanism is arranged. It’s meant to keep a regular consistent RPM.

If the winds are low, it opens all the way up. If the RPM starts to exceed a certain limit, it starts to furl in until it reaches a stable RPM again.

Assuming they’re built structurally sound enough, Harmony Turbines could indeed keep functioning right through a category 5+ hurricane, assuming a tree doesn’t get blown into it or whatever, but basically everything is prone to storm debris anyways.

Regardless, like I said, consider the strength in numbers vs the absurdity of building planes as big as a football field…

The idea is rather than the complexities of making conventional turbines even bigger and dealing with the logistics of even building and installing them, the same land space could have potentially a thousand or more smaller vertical Harmony Turbines in the same land space as a single conventional large turbine.

Hell, they could even share the same land space as the existing large turbines. And they’re much more practical to install, you could even have one or two or so in your own back yard.

I get that the idea is to tap into stronger upper atmosphere winds, but if you consider the idea of strength in numbers, then I think many Harmony Turbines could definitely hold their own and deliver a good bit of power, even if they are inherently meant to be closer to the ground.

Plus it doesn’t require an airplane as big as a freaking football field to ship the parts around. Like, how green is such a large airplane anyways, how much fuel would such a large plane take? 🤔

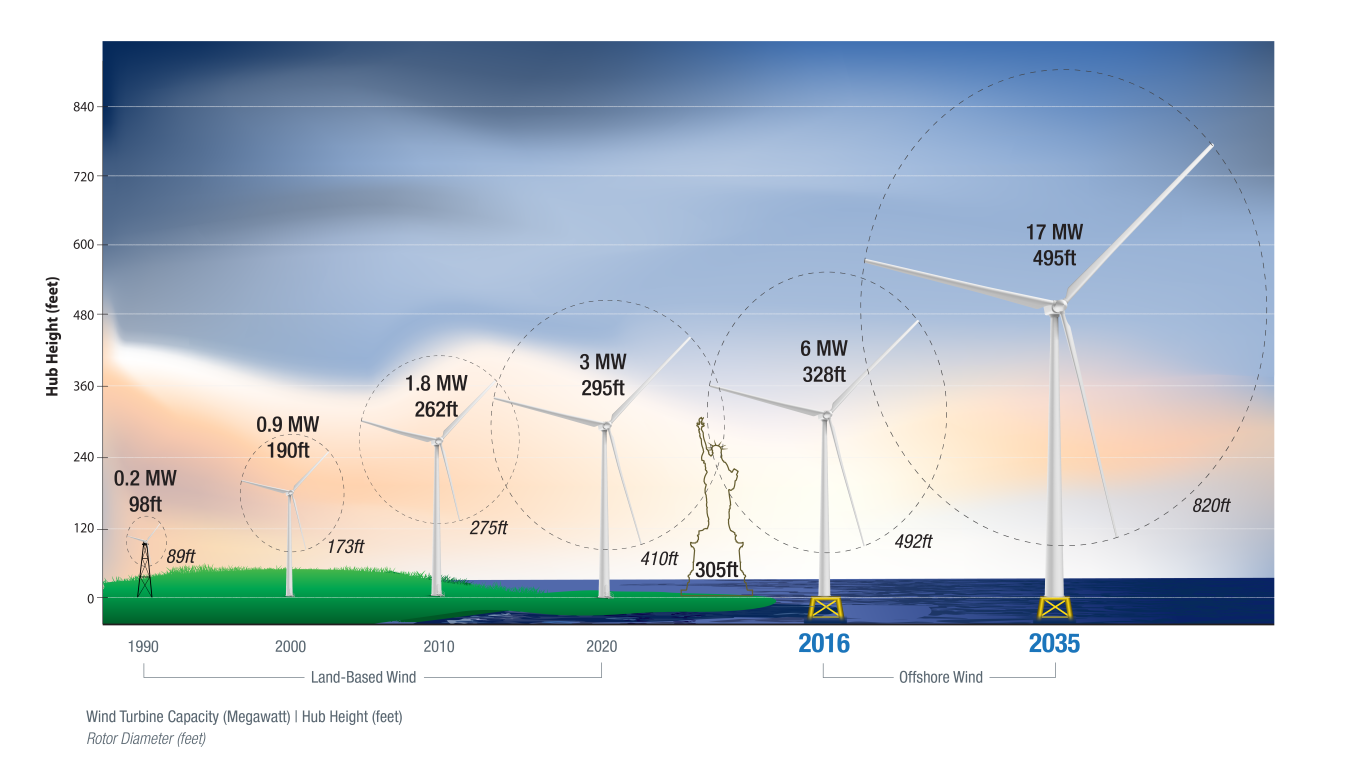

Check out this DOE page for more info on turbine scale: https://www.energy.gov/eere/articles/wind-turbines-bigger-better

I never said it was anywhere near a 1:1 comparison as far as output power, that should be plenty obvious. But a rather large array of Harmony Turbines could be installed in the same land space as one conventional turbine.

Hell, it’s not entirely impractical to have your own Harmony Turbine in your own back yard…

Their prototype unit is 400 watts, based on their deck their target is residential use.

While “a lot” would fit in a the footprint of a large turbine, 42,500 would not, which is how many would be needed to be equivalent to the large turbines the article is talking about, and I’d bet that many Harmony Turbines would cost more as well.

Scale efficiency for grid scale wind projects is the bottom line, and bot accessing steadier and stronger high altitude winds with taller turbines and using larger diameter blades gain efficiency beyond what any fleet of smaller turbines can match.

Not to say that larger scale vertical axis turbines are completely out of the picture, but they suffer from irregular bearing loading which wears out the drive train much faster among other issues. As of now large scale horizontal axis bladed turbines are far ahead in term of both cost and space efficiency. It would take something very groundbreaking to change that.

No need to die on this hill, it’s just different technologies for different applications, there is a place for both.

Irregular bearing loads can be largely relieved using permanent magnet levitating bearings to basically completely relieve the weight off of the mechanical bearings.

Also keep in mind that Harmony Turbines catch wind equally from any direction, without having to regularly adjust and turn for changing wind directions.

I’ve also noticed a bit of a flaw in the Harmony prototypes, they’re making their own generator mechanism and winding their own coils, around solid steel cores rather than the known more efficient design using many stacked discs as the electromagnetic windings used in everyday generators, alternators and motors.

Yes sure there’s room for improvements, their project is fairly new, but I still see more strength in numbers rather than ridiculous large size.

Like, how much fuel goes into an airplane the size of a football field again? How is such a large plane helping the green cause at all?

To not dismiss your perspective out of hand, in order to use smaller vertical-type mills and still tap higher altitude winds on masts would require support structures that can keep many more turbines aloft to supply the same electricity, and the electrical infrastructure to merge all the turbine electrical output and balance the loads to give a stable denoised power output to the grid.

The result is a much lower weight to power density in the smaller turbines, meaning much more expensive structural supports, and much more expensive power routing and station infrastructure. This makes such projects non-viable as they wouldnt be able to charge enough for the electricity to pay off the infrastructure over the lifetime of the turbines.

Smaller turbines like the one you posted DO have a great place in the power mix, for example for potential installation at the top of skyscrapers where the support infrastructure is already paid for by other uses (though the loads have to be accommodated by the building design, which still adds cost), or in low-altitude areas where steady winds exist and there is specific moderate electrical demand, such as in valley ports on islands or more remote coastal towns. In those cases larger mills would overproduce electricity demand, so smaller turbines at lower altitude are a good fit.

I can see more like where people could have one or three or so Harmony Turbines in their own yard, along with solar panels on their roof.

If enough people managed to adopt these sort of technologies on their own property, it could definitely put a good chunk of potentially excess power right back into the grid.

Yes, this definitely should be a part of the energy mix, we are about to experience an energy crisis in the US due to bad changes in policy. We need to deploy wind at all scales.

Didn’t realise they would be transported by plane, only ever seen them going out by barge.

I’ve seen one transported by ground vehicles. It was a humbling experience.

They can’t be, yet, as the article points out - they’re building a new plane

They are already building wind turbines, this is just about bigger ones. Would have thought they are assembled by where ever you load the barge

But do we really need bigger turbines? It seems the ones we have work fine.

“GigaWind turbines would decrease the cost of energy by 20 to 35 percent while increasing output by 10 to 20 percent” - efficiency matters